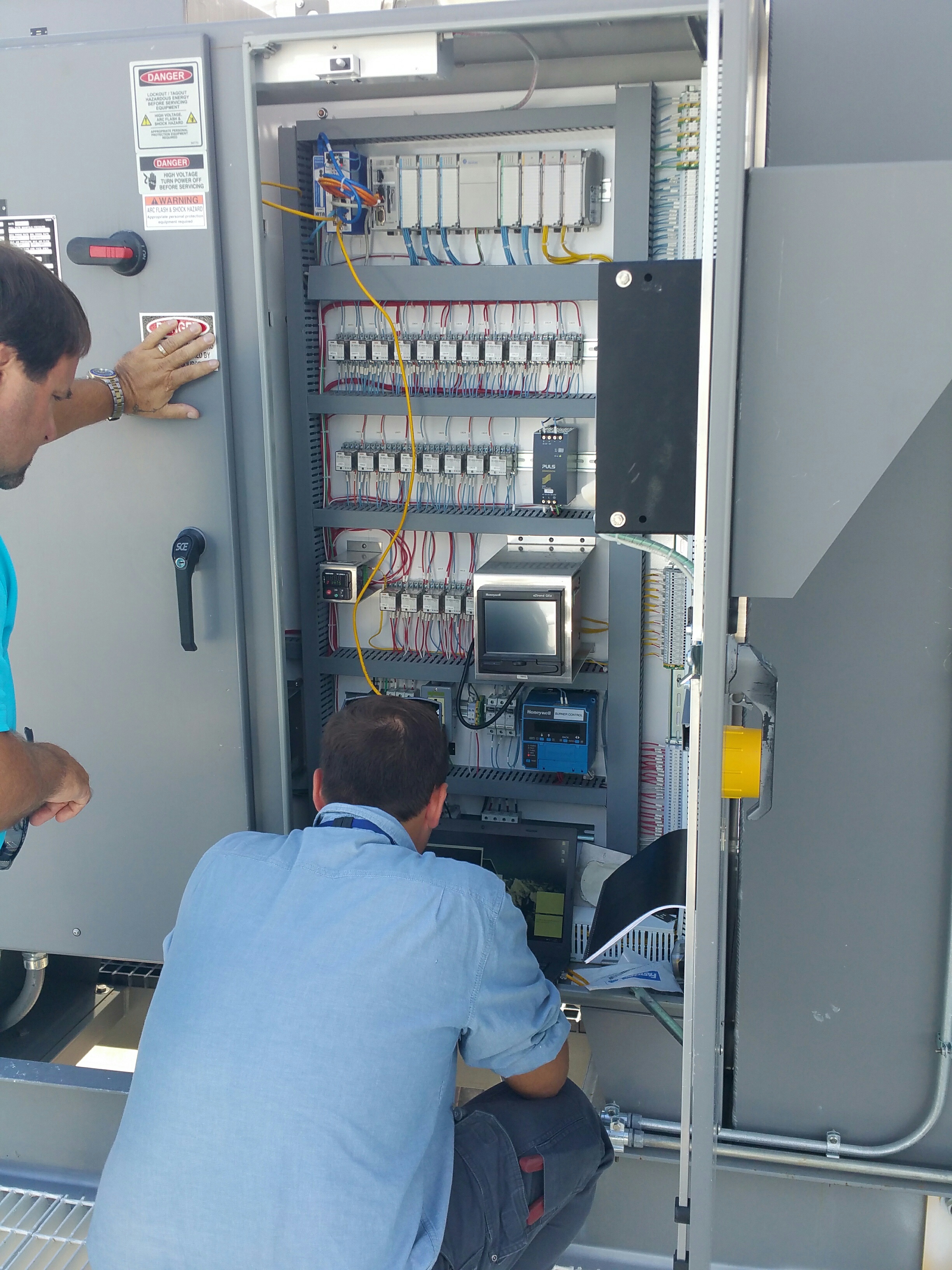

Semiconductor Production Facility, Thermal Oxidizer

About: The facility in question has nearly a dozen class 1000 clean rooms. In these environments are several processes that produce acidic vapor and gasses. A Thermal Oxidizer cleans and neutralizes that vapor and air.

Goal: Integrate the Thermal Oxidizer into the wider building control system front end and historian software.

Solution: The piece of equipment had a BACnet communication option to integrate into a building control system. We create all the BACnet tags for the equipment, created the system network, created custom front end graphics and pulled out all required data points. In addition we added them to a historical trend database with trendable data and custom mappings.

Pioneers

About: Pioneers mobilizes teams to glorify God among unreached peoples by initiating church- planting movements in partnership with local churches.

System: Pioneers global headquarters located in Orlando Florida includes a two story office building that is served by a fifty ton air-cooled variable air volume RTU. Each floor consists of approximately fifteen parallel fan terminal units.

Goal: Improve system reliability and resolve constant comfort complaints on the second floor.

Solution: Automated Mechanical Services (AMS) teamed up with one of their air-conditioning contractor customers to replace the RTU and retrofit the second floor VAV Terminal Unit controls to ASI Controls. AMS also provided a web based graphical interface to the newly retrofitted VAV Terminal Units and the new Carrier RTU via BACNet.

Countryside Towers

About: Countryside Towers is a six story multi-tenant office building located in Clearwater, FL.

System: The system consists of three air-cooled screw chillers configured as a primary-secondary pumping system. There are eleven variable air volume air-handling units and approximately 110 pressure dependent, reheat VAV Terminal Units. The control system is a mixture of DDC and pneumatics.

Goal: Prepare two floors for a new tenant.

Solution: Automated Mechanical Services (AMS) was hired to evaluate the existing system to determine what was necessary to prepare a reliable system for a new tenant. AMS retrofitted many of the existing pneumatic controls serving the VAV Terminal Units to DDC utilizing ASI Controls.

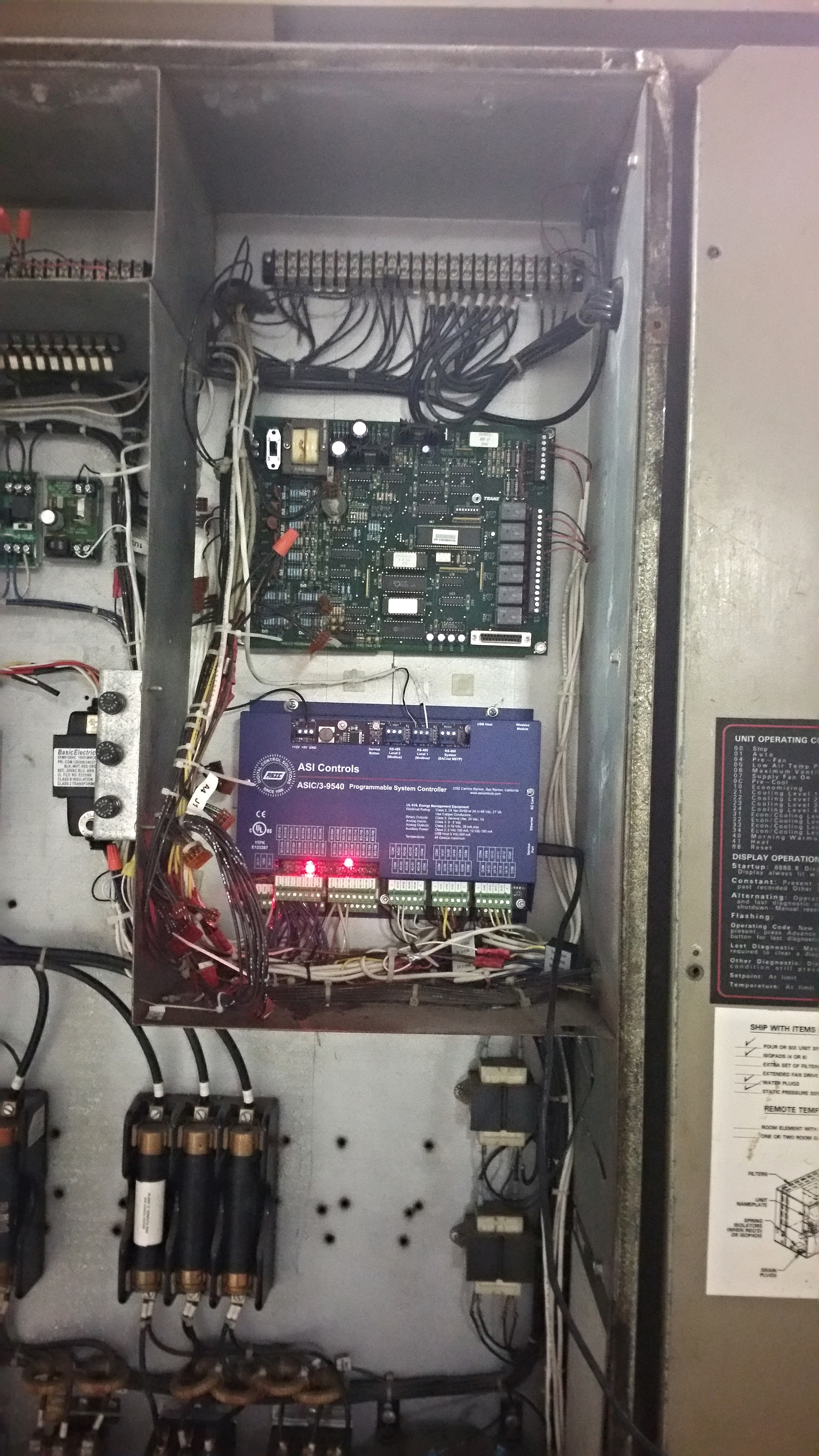

Clearwater Tower

About: Clearwater Tower is a twelve story multi-tenant office building located in Clearwater, FL.

System: The system consists four variable air volume water cooled package units, approximately 88 Trane first generation DDC VAV Terminal Units and a condenser water plant.

Goal: Develop and implement a strategy to convert a first generation Tracer control system in which parts are no longer available to a new state of the art DDC control system.

Solution: AMS developed and implemented a strategy to convert VAV Terminal Unit and AC Unit controls to ASI Controls as the Trane controls fail.

Wycliffe Bible Translators

About: We were recently hired to investigate and solve an issue in which three split systems serving the same meeting room were fighting each other. After investigating we learned that often times one unit may be cooling while the other was heating. We also noticed that one unit seemed to constantly be cooling while the others sat idle.

System: The three dual circuit six ton systems were being controlled by three Trane ZN517 controllers

Goal: Our suggested resolution was to install one programmable controller to control all three systems as one.

Solution: We essentially programmed the controller to act as a six stage cooling / three stage heating temperature controller that controlled the units capacity based on the average of three space temperature sensors. We also included the ability to automatically alternate the stages so that all units would receive equal wear. This controller was added to the clients existing computer network with the data presented in a graphical format to any phone or computer that’s able to connect to the internet. This enhancement resolved all issues and concerns expressed by the client.